Our Products

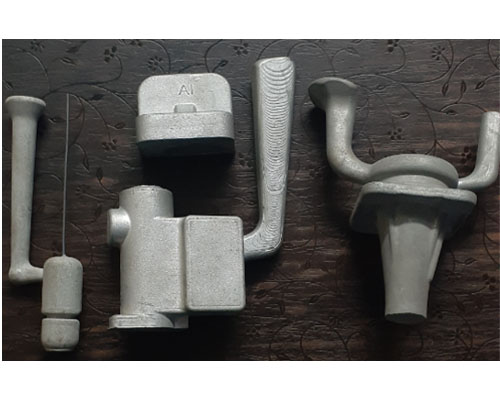

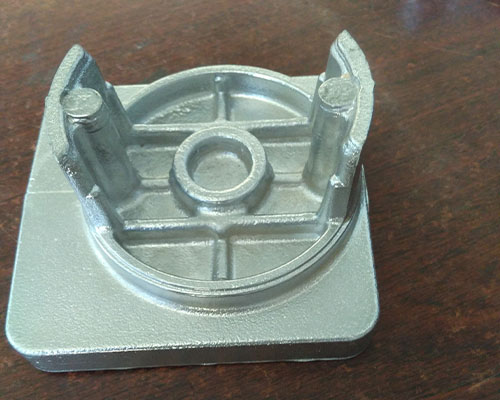

GDC Components

Gravity Die Casting (GDC) components play a pivotal role in modern manufacturing, particularly in industries where high-quality metal parts are essential. This process involves pouring molten metal into a metallic tool or die under the influence of gravity, allowing the metal to fill the mold cavity and take the shape of the desired component. One of the key advantages of GDC is its ability to produce parts with high dimensional accuracy and excellent surface finish, making it suitable for components where precision is critical.

- High Dimensional Accuracy: Gravity die casting produces components with tight dimensional tolerances, ensuring precision in the final part.

- Excellent Surface Finish: The process results in components with smooth surfaces, reducing the need for additional finishing operations.

- Complex Shapes: GDC is capable of producing components with intricate designs and complex geometries, expanding design possibilities.

- Cost-Effective for Medium to High Volumes: While initial tooling costs can be high, gravity die casting becomes cost-effective for medium to high production volumes due to its efficiency.

- Material Versatility: GDC can be used with a variety of metals and alloys, including aluminum, zinc, and copper-based alloys, offering flexibility in material selection.

- Low Porosity: Gravity die casting produces components with low porosity, ensuring high integrity and strength.

- Automotive Industry: GDC components are widely used in the automotive industry for engine parts, gearbox housings, suspension components, and structural parts due to their high strength and dimensional accuracy.

- Aerospace Industry: In the aerospace sector, GDC components are utilized for aircraft components requiring high strength-to-weight ratios, such as engine parts, brackets, and structural components.

- Electronics Industry: GDC is used in the electronics industry for producing components such as heat sinks, housing for electronic devices, and connectors due to its ability to produce complex shapes with good thermal conductivity.

- Construction Industry: GDC components find applications in the construction industry for producing architectural components, decorative elements, and structural parts due to their strength and durability.

- General Engineering: GDC components are used in various general engineering applications where high-quality metal parts with complex shapes are required, such as in machinery, tools, and equipment.