Our Products

Sand casting components

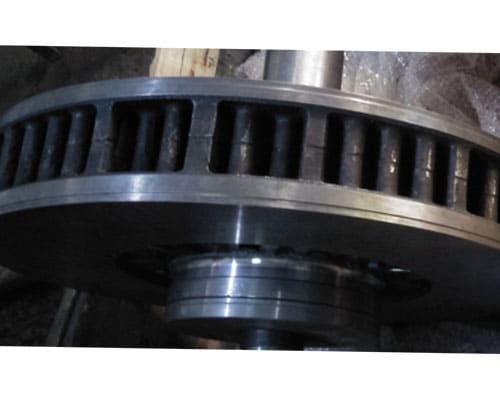

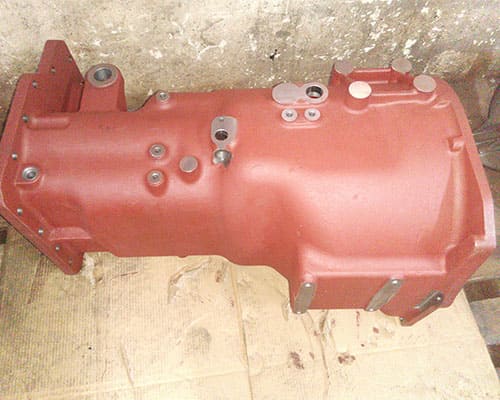

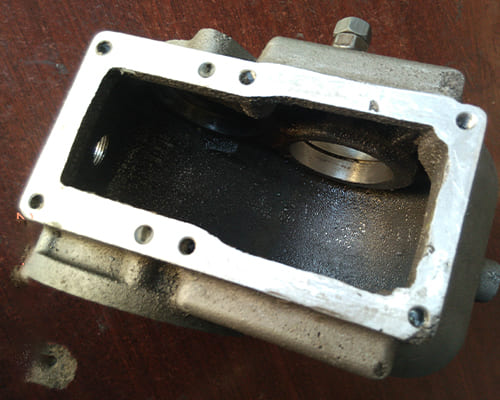

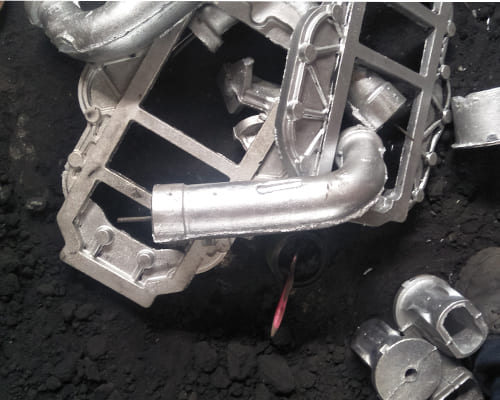

Sand casting components are parts or products manufactured using the sand casting process, one of the oldest and most widely used casting methods. In sand casting, a pattern of the final part is pressed into a sand mixture to create a mold cavity. Molten metal is then poured into the mold cavity, where it solidifies to form the final part. Sand casting is versatile and can produce components of various sizes and complexities. Common sand casting components include engine blocks, cylinder heads, pump and valve components, gearbox housings, manhole covers, machine tool bases, large pipe fittings, hydraulic cylinder components, railway parts, cookware, and decorative pieces.

- Versatility: Sand casting can be used to produce a wide range of shapes and sizes, from small components to very large parts.

- Cost-Effectiveness: It is relatively inexpensive compared to other casting methods, making it suitable for large-scale production.

- Complexity: Sand casting can accommodate complex geometries and internal structures, including cores for hollow parts.

- Material Compatibility: It is compatible with a variety of metals and alloys, including iron, steel, aluminum, and bronze.

- Tooling: Tooling costs are lower compared to other methods, as the patterns used in sand casting can be made from inexpensive materials.

- Surface Finish: The surface finish of sand cast components can vary, but it is generally rougher compared to other casting methods. Post-casting finishing processes may be required for certain applications.

- Lead Time: The lead time for producing sand cast components can be longer compared to other methods, as the mold-making process can be time-consuming.

- Environmental Impact: Sand casting generates waste sand, which can be recycled, but it also requires significant energy for melting the metal.

- Automotive Industry: Engine blocks, cylinder heads, transmission cases, and other large automotive components are often produced using sand casting.

- Aerospace Industry: Sand casting is used for producing large structural components, such as engine parts and aircraft frames.

- Heavy Machinery: Components for heavy machinery, such as gearboxes, housings, and hydraulic parts, are often made using sand casting.

- Railways: Rail components like brake shoes, couplers, and brackets are commonly manufactured using sand casting.

- Construction: Manhole covers, drainage grates, and other infrastructure components are often produced using sand casting due to its ability to produce large, durable parts.

- Pumps and Valves: Various components of pumps, valves, and other fluid handling equipment are produced using sand casting.

- Art and Sculpture: Sand casting is also used in art and sculpture to create metal sculptures and decorative pieces.

- General Manufacturing: Sand casting is used in various other industries for producing a wide range of components, from small parts to large, complex structures.