Our Products

Reverse engineering

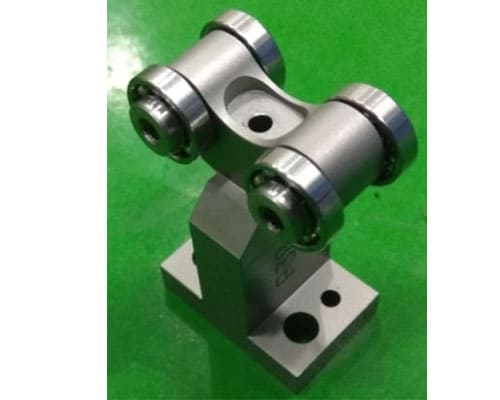

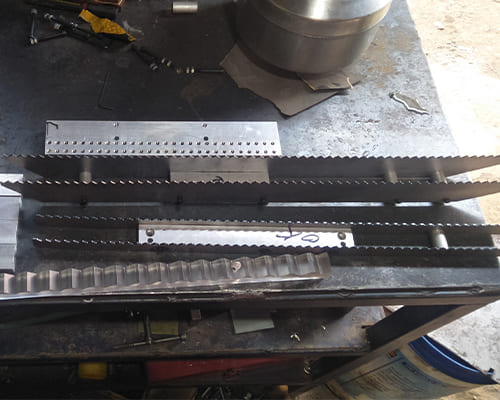

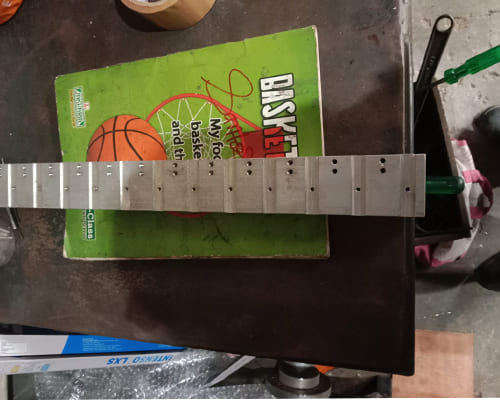

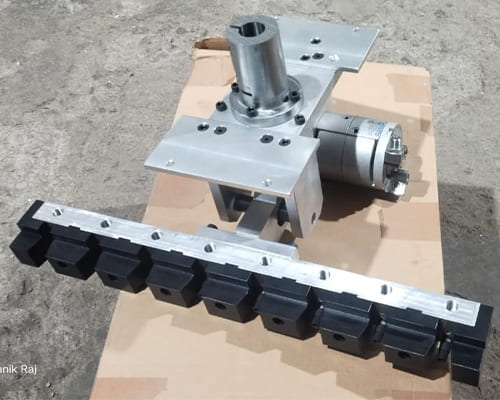

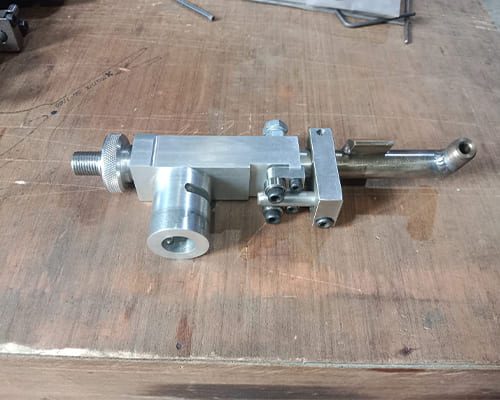

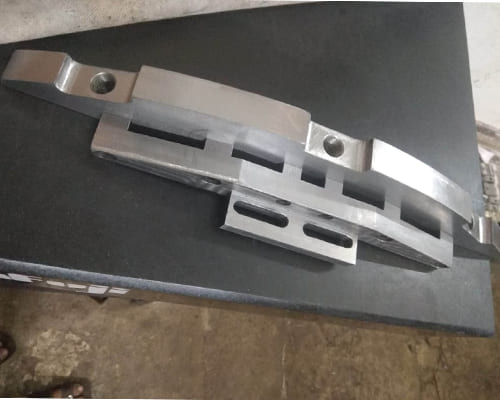

Reverse engineering components involves the process of disassembling a product to understand its design, functionality, and manufacturing methods. This process is typically used when the original design documentation or specifications are unavailable, outdated, or incomplete. Reverse engineering can be applied to various components, including mechanical, electronic, and software components. The goal of reverse engineering components is to create detailed documentation, models, or drawings that can be used to replicate or modify the component.

- Disassembly: The process involves carefully disassembling the component to analyze its individual parts and how they are assembled.

- Measurement: Accurate measurements of the component's dimensions and features are taken using various tools and techniques such as calipers, 3D scanners, and coordinate measuring machines (CMMs).

- Analysis: The collected data is analyzed to understand the component's design, materials, and manufacturing methods.

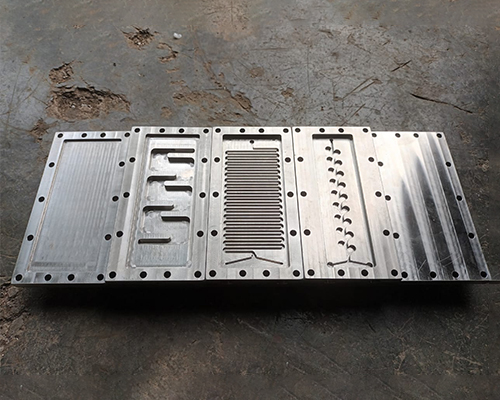

- Documentation: Detailed documentation, including drawings, models, and specifications, is created to represent the component's design and functionality.

- CAD Modeling: Computer-aided design (CAD) models are often created based on the collected data to replicate or modify the component.

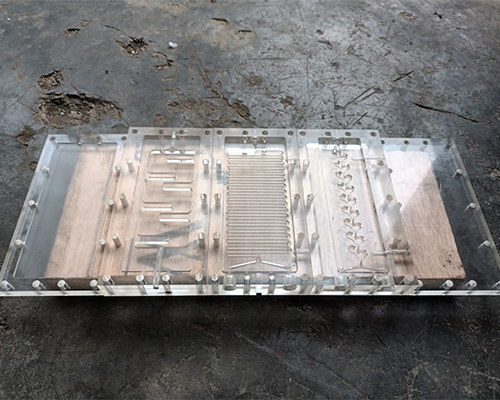

- Testing and Validation: The reverse-engineered component may be tested to ensure that it meets the required specifications and functionality.

- Iterative Process: Reverse engineering is often an iterative process, where the component is continuously analyzed and modified to achieve the desired outcome.

- Legacy Component Replication: Reverse engineering is used to replicate components for which the original design documentation is no longer available.

- Component Improvement: It is used to improve existing components by identifying design flaws or inefficiencies and proposing design modifications.

- Interoperability: Reverse engineering can be used to create compatible parts or components that can work with existing systems or equipment.

- Competitive Analysis: Companies may use reverse engineering to analyze competitor products and gain insights into their design and manufacturing processes.

- Customization: Reverse engineering can be used to customize components to meet specific requirements or to adapt them to different applications.

- Obsolete Component Replacement: It is used to replace obsolete components with modern equivalents that meet the original specifications.

- Quality Control: Reverse engineering can be used to verify the quality and accuracy of components produced by suppliers.

- Intellectual Property Protection: Companies may use reverse engineering to protect their intellectual property by analyzing and identifying potential infringement of their patents or designs.